Mass Flow Feeders

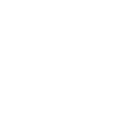

The Geomate™ is a Mass Flow Vibratory Feeding System, incorporating both a mass flow hopper and mass flow feeder. This is not your typical vibratory feeder. First, the hopper wall angles are designed to be steeper than the product’s wall friction characteristics thereby promoting material flow in all areas of the bin. Second, the outlet is sized larger than the product’s arching dimension, thereby preventing bridging. In addition the Geotray™ feed tray promotes mass flow by shearing the entire cross sectional outlet of the hopper. This “live bottom” vibratory action, working in unison with the MassMate™ hopper, provides a true mass flow vibratory feeding system. First in, first out, no moving parts and an industry best 2-year warranty translates into the lowest operating cost in the industry.

The BrickMaster™ offers a breakthrough in coating feeder technology for the brick industry. Whether coating the face, the header, or both, the BrickMaster™ Mass Flow Vibratory Coating Feeder can improve your brick quality while minimizing dust and spillage in the coating area. Manual, semi-auto and automatic system solutions available. 3Sigma offers complete brick mixture solutions: raw ingredient compounding, mixing, conveying, brick coating and reclamation systems.

We also provide complimentary equipment and components, such as weighing scales, blenders, IBC Systems, magnets, and more.

Geomate™ Mass Flow Feeders

Mass Flow Feeders are the engineer’s Batching Feeder of choice as they provide Pulseless Feeding and Instant Off flow control. 3Sigma offers a proprietary Loss-in-Weight or Gain-in-Weight Mass Flow Vibratory Feeder, the GeoMate™, for applications which meet your design requirements.

The Geomate™ is a Vibratory Feeding System, incorporating both a mass flow hopper and mass flow feeder. First, the hopper wall angles are designed to be steeper than the product’s wall friction characteristics thereby promoting material flow in all areas of the bin. Second, the outlet is sized larger than the product’s arching dimension, thereby preventing bridging. In addition the Geotray™ feed tray promotes mass flow by shearing the entire cross sectional outlet of the hopper. This “live bottom” action, working in unison with the MassMate™ hopper, provides a true mass flow vibratory feeding system. First in, first out, no moving parts and an industry best 2-year warranty translates into the lowest operating cost in the industry.

Inherently the GeoMate™ mass flow feeder will produce a higher degree of accuracy than a conventional screw feeder and it will provide this benefit without any moving parts

1) Dependability/Maintenance

The GeoMate™ mass flow feeder has no moving parts. The vibratory feeding system operates on a mass flow basis, without the following moving parts typically in a screw feeder system: screw, sprockets, bearings, bushings, multiple DC/AC drives, motor brushes, agitators, shafts and seals.

The GeoMate™ feeder is not affected negatively by the abrasive or the very fine powders (magnesium, iron oxides, etc) or the cohesive products (clay) that you use. Our vibratory feeder has loss-in-weight and gain-in-weight capabilities, for gravimetric feeding and volumetric feeding.

- Abrasive products will abrade the screw in a screw feeder, in many cases rendering it useless in months, due to the high wear. Continuous replacements are costly ($800 to $2,000 per screw). The GeoMate™ vibratory feeder does not force material against a surface, such as a screw against the discharge tube, thereby eliminating friction and wear.

- Fine products. It is a well known fact that fine materials, -100 to -325 mesh, will work their way past the seals, where the feed screw attaches to the drive shaft and, in time, will bind the feed screw, causing a failure of the screw feeder. Air purge systems and special seals improve this, but have not been able to eliminate it. The GeoMate™ vibratory feeder has no unions, no shafts, no seals thereby eliminating this problem.

- Cohesive products. Finally, you will never again hear the “squeal” of a feed screw binding within the outlet tube as material builds up, heats up and hardens inside the screw feeder. This generally leads to the screw twisting itself up in the hopper leading to downtime and high replacement costs. The GeoMate™ vibratory feeder eliminates this problem.

- Fibers. Our patented rod tray can effectively feed steel, wool, and steel fibers.

2) Accuracy

Due to the inherent design of the GeoMate™ mass flow feeder the final batch accuracy will be much greater than that of a screw. As seen during our demonstration the output is incredibly consistent whether feeding at the fast speed or the dribble speed. This creates a very consistent amount of product in “free fall” time and time again, which is compensated for with the control’s preact function. This fact, Instant Off, without Plopping, provides optimal batch accuracies.

3) Investment

The short-term investment of the Geomate™ vibratory feeder is very similar to a comparable screw feeder, while the long-term investment is much less, as there are literally no wear parts on the feeder! Screw feeders require replacement parts period. Feed screws, sprockets, seals, motor brushes and bearing assemblies are typical replacement parts on a screw feeder system. The GeoMate™ vibrator feeder comes with a 3-year warranty.

4) Cleaning

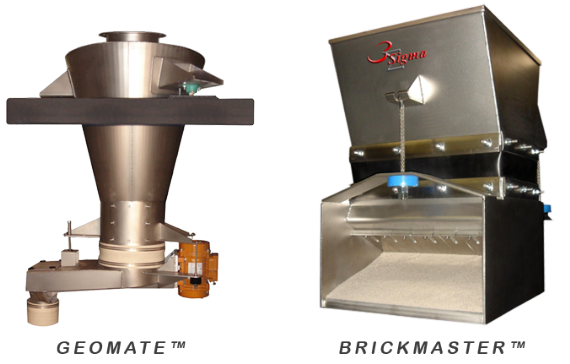

The GeoMate™ vibratory feeder is easy to empty and clean. Remove one quick-disconnect clamp and the tray swings open for complete cleaning.

5) Safety

As there are no moving parts in the Geomate vibratory feeder, there is no potential for worker injury.

Quick Access to Inside of Tray

Easy Clean and No Moving Parts

Remove quick-disconnect clamp for Easy Clean

BrickMaster™ Coating Feeders

The BrickMaster™ mass flow feeder offers a breakthrough in vibratory coating feeder technology for the brick industry. Whether coating the face, the header, or both, the BrickMaster™ Coating Feeder can improve your brick quality while minimizing dust and spillage in the coating area. Manual, semi-auto and automatic system solutions available.

3Sigma offers complete brick mixture solutions: raw ingredient compounding, mixing, conveying, brick coating and reclamation systems.

- Feed sand, clay and shale mixtures

- Mass Flow Feeding - no more operator interface

- Minimize dust

- Mount feeder <1” above brick line

- Adjust coating width in minutes

- 100:1 coating turndown rate

- Volumetric and Gravimetric systems

- Unsurpassed 3-year warranty

Minimize Dusting

The unique vibratory feeder and drive arrangement offered allows the feeder to be placed <1” above the brick line, eliminating most transient dust. The hopper inlet is completely sealed, completely eliminating in feed dusting.

Eliminate Operator “Interface”

Each BrickMaster™ coating feeder is designed for mass flow. The vibratory feeder's hopper slopes are designed to ensure all product flows at one time, while the outlet is sized to prevent bridging. The vibratory feeder's Mass Flow design ensures a first in, first out flow pattern, and, the elimination of operator “interface”.

Adjustable Coating Width

Although most vibratory coating feeder units are designed for a specific coating width, specialty RatePlates™ can be provided to allow for coating width adjustment in minutes.

Adjustable Flow Rate

The BrickMaster™ Vibratory Coating Feeder flow rate can be adjusted three ways:

- Each unit is controlled by a VFD which typically provides a 10:1 turn down range.

- RatePlate™ adjustments

- Vibrator adjustments

These can provide significant rate changes.

- Each unit is controlled by a VFD which typically provides a 10:1 turn down range.

- RatePlate™ adjustments

- Vibrator adjustments

These can provide significant rate changes.

Contact Us - Guaranteed Response within 24 Hours!