LaborSave™ Automatic Sack Emptying Systems

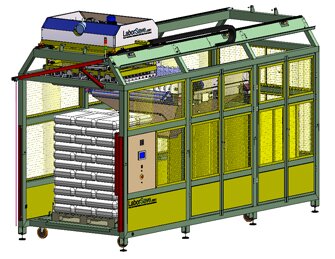

The patented LaborSave™ Debagger is a fully automatic, highly effective sack emptying system that results in significant savings from increased efficiency, less waste of raw material and less labor. This cost-efficient debagging machine has four models to meet a range of needs. LaborSave™ automates the entire process; from bag lifting, to bag slitting, to bag emptying, to discarding the bag. Using mechanical grippers enables the handling of most types of sacks, including plastic, polypropylene, paper, and burlap.

Laborsave Debagger Machine

Watch the LaborSave in Action!

The LaborSave™ Robot enables the handling of most methods of sack arrangement on the pallet, as well as inclinations of up to 25 centimeters. In almost every circumstance, more than 99.99% of the sackʹs contents are being emptied and collected. LaborSave is suitable for the plastics industry, food industry, chemical industry, pharmaceutical industry and building industry. 3Sigma is proud to provide the truly unique LaborSave™ Debagging System for plants and factories in the US, Canada, and Mexico. We also provide complimentary equipment and components, such as dust collectors, mechanical and pneumatic conveyors, and silos.

Features and Advantages

- 400-1300 Sacks Per Hour

- More than 99.99% Empty

- Automatic Sack Unloading and Emptying

- Total Elimination of Manual Lifting

- A Clean Bag Emptying Environment

- Suitable for Standard Sack Types

- Greater Throughput

- Increased Efficiency of Raw Materials

- Reduced Labor

- Enhanced Safety

- Reduced Contamination Risk

- Enhanced Flexibility

LABORSAVE MODELS

The LaborSave™ is ideal for loading silos, day tanks or bulk trucks. 3Sigma Systems offers the LaborSave as a stand-alone system and also offers a complete system solution including pneumatic or mechanical conveying, silos, day tanks, bin vent filters, level controls and discharging equipment to meet your requirements.

LC LaborSave Model

LABORSAVE - AUTOMATICALLY UNLOAD 400 SACKS PER HOUR WITH THE LC MODEL

CMT offers the most effective automatic sack emptying system in the industry. The LaborSave LC model has a maximum throughput of 400 sacks per hour. It is the most compact model of this debagging system, and is ideal for small factories. The LC is the compact version of the HC model created by Laborsave, who was the first to introduce a truly automatic sack emptying solution, and continues to lead the industry in product advancements.

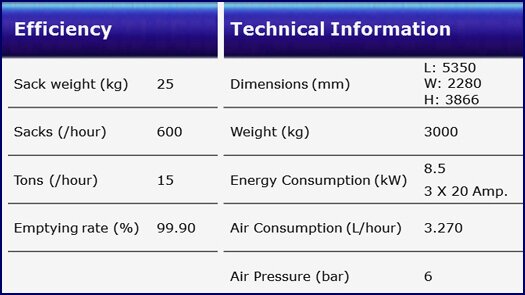

HC LaborSave Model

LABORSAVE - AUTOMATICALLY UNLOAD 600 SACKS PER HOUR WITH THE HC MODEL

CMT offers the most effective automatic sack emptying system in the industry. The HC model has a maximum throughput of 600 sacks per hour. The more compact HC is ideal for small factories with a smaller budget. The HC is the original model created by Laborsave, who was the first to introduce a truly automatic sack emptying solution, and continues to lead the industry in product advancements.

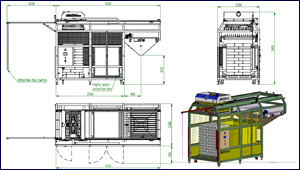

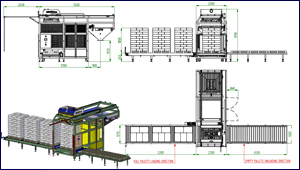

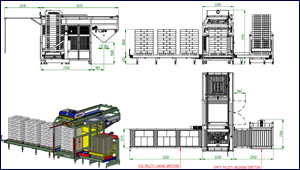

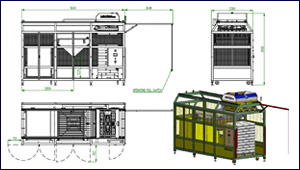

HC Model Stand Alone Unit Drawing

HC Unit with Conveyors Drawing

HC Unit with Conveyors, Stackers Drawing

G2 LaborSave Model

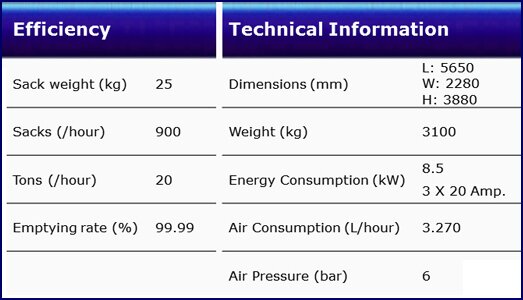

LABORSAVE - AUTOMATICALLY UNLOAD 900 SACKS PER HOUR WITH THE G2 MODEL

Carolina Material Technologies offers the most effective automatic sack emptying system in the industry. The G2 model Laborsave has a maximum throughput of 900 sacks per hour. The larger G2 model empties 99.99% of sack material, providing slightly more cost savings than the HC. The G2 model is the second generation LaborSave, and is ideal for medium-large sized factories

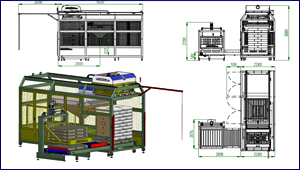

G2 Model Stand Alone Unit Drawing

G2 LaborSave Unit with Stackers Drawing

HC LaborSave with Conveyors, Stackers Drawing

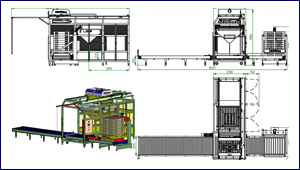

VHC LaborSave Model

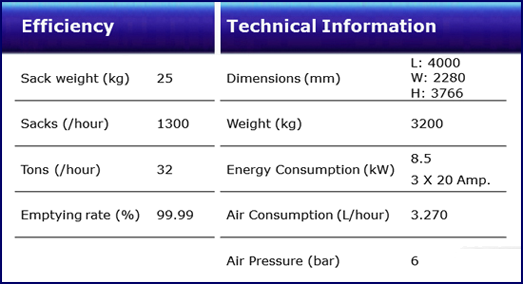

LABORSAVE - AUTOMATICALLY UNLOAD 1,300 SACKS PER HOUR WITH THE VHC MODEL

Carolina Material Technologies offers the most effective automatic sack emptying system in the industry. The VHC model Laborsave has the capacity to empty out 1300 sacks per hour. The VHC is the largest Laborsave model, and it empties 99.99% of sack material, making it the most cost-effective and most sold model. Due to the capacity of the VHC, this model is ideal for large factories.

Contact Us - Guaranteed Response within 24 Hours!