Bulk Bag Unloaders for Dust-Free Discharging

Bulk Bag Unloader with Massage-It Agitation Paddles

Dust-Free Bulk Bag Unloading Technology

This Super Sack Unloading system boasts the Contain-It™ Chamber. This is a large, User-Friendly Access Chamber that allows the operator to easily tie, retie, and handle FIBC Bulk Bags and Super Sacks in an enclosed, dust-tight chamber. No more spilling excess material on your plant floor when shaking or handling the bag. 3Sigma offers three Main Models (Hoist and Trolley Model, Short Frame Model, and Fork-Truck Loaded Model) with two types of bulk bag agitation: Paddle Agitation (Massage-It™) and Vertical Vibration (Shape-It™). Each 3Sigma Bulk Bag Discharge Station is truly Industrial Grade. Each unit is designed based upon your products, your process, and your needs. We offer two styles of bulk bag agitation – Paddle Agitation (Massage-It™) and Vertical Vibration (Shape-It™). With your product we have recommended our Massage-It™ agitation system to properly discharge your product. If you prefer our Shape-It™ system, please advise and we can requote. In addition, please keep in mind that we offer six levels of dust control – choose the level that is right for you.

Features and Goals

- Proper discharging of each product.

- Minimize airborne dusts – protect your operators and the work environment.

- Improve ergonomics – minimize operator time and effort in unloading bags.

- Improve the speed in unloading your bags. You desire to unload a bag in ___ minutes.

- Re-tie and remove partially emptied bags.

- Eliminate the introduction of contaminants into your process – ensure a positive seal with your bulk bag.

- Empty bags to the greatest extent possible, even most dust.

- Eliminate the mess associated with disposing of the emptied bulk bags.

- Heavy duty design that minimizes maintenance items and expense.

Overview

Bulk bag dischargers are typically implemented when capacity requirements dictate a change from 50 lb. bulk bags to save labor costs and to minimize dust. The most crucial aspect in providing you with a successful bulk bag unloader is understanding the bulk bag(s) to be used, your goals and concerns. Many suppliers overlook the actual bulk bag and dive into offering you their standard bulk bag unloader – the “one size fits all” mentality. Bulk Bag items of concern include: Dimensions; Lined or Unlined; Loose Liner, Tabbed Liner or Glued Liner Flat Bottom or Cone Bottom; Single Trip or Multi-Trip; Bulk Bag Outlet Spout Dimensions; Bulk Bag coatings, etc. We can also provide supplementary equipment such as screw conveyors, dust collectors, rotary valves, aeromechanical conveyors, and more.

General Bulk Bag Unloader Customer Goals

- Dust Free Bulk Bag Unloading.

- Unload your densified product reliably with a Bulk Bag unloader.

- A Bulk Bag Discharger for Total Bulk Bag Discharging

- Minimal moving parts/ Minimal maintenance.

Videos

BBU Massage-It Model Promo

3Sigma's Bulk Bag Unloading System with the Massage-It™ Agitation Paddles ensures that material flows out of the bag with ease.

Super Sack Unloader - Titanium Dioxide

Unloading Titanium Dioxide from a Bulk Bag using a 3Sigma Bulk Bag Unloader.

BBU to Feeder with AMC Conveyor

A Shape-It™ Bulk Bag Unloader was provided to properly discharge PVA powder. Material is unloaded into a GeoMate™ Vibratory Feeder, then discharges into a bag dump hopper, which feeds directly into an Aeromechanical Conveyor.

Proper Bag Discharging

Proper bag agitation is crucial in discharging your product. 3Sigma offers three methods of agitation, recommending the proper bag agitation system for your products, all with a guarantee of product discharge.

MASSAGE-IT™ AGITATION SYSTEM

Dual agitators are used with the most difficult to discharge products. Heavy duty pipe agitators are used to ensure product discharge, with Massage-It agitators pivoting a full 90 degrees. The pneumatically operated agitators provide plenty of force to loosen the material in the super sacks.

3Sigma Dual Agitators in Action

SHAPE-IT™ DISCHARGING SYSTEM

The compacted bulk bag is set into the bag shaping platform. Vertical Vibration is then used to shape the bulk bag to the steep sloped platform prior to opening the bag. Once set the bag spout is easily accessed and the vertical vibration is used periodically, if needed, to discharge product. All with no moving parts.

Before/After

SHAPE-IT™ VERTICAL VIBRATION

Fully Welded Bag Shaping Support Platform

MASSAGE-IT™ DUAL AGITATORS

The pneumatically operated agitators push material from the edge of the bag to the outlet flow channel while breaking compacted material.

Total Containment

CMT’s Bulk Bag Unloading System offers a completely dust-tight access chamber that contains dust within a large, easy to access chamber. Our pneumatically actuated bulk bag spout clamping system completely seals the bulk bag outlet spout thereby eliminating the most poignant dust leakage potential. Contact us for a complete project analysis.

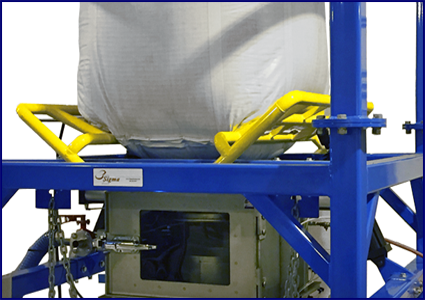

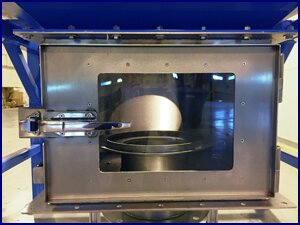

CONTAIN-IT™ BAG ACCESS CHAMBER

- Extra Large Chamber

- Sealed Bag access

- Contain all leaks and spill

Our bulk bag unloaders minimize dusting, as the bag spout is connected to an internal cylinder, located within the isolation chamber. The bulk bag is clamped via air cylinders thereby providing a positive seal between the bag and downstream equipment within the access chamber.

Please notice how LARGE this access chamber is. Compare this to “gull wing” doors and small square enclosures that make it very difficult to access the bag.

Dust Extraction Port – This port is connected to the access chamber, pulling any dust that may be present due to leakage at the bag seams or stitching, which is especially prevalent with unlined bulk bags. This is located far above the material contact area, allowing for positive dust evacuation, as it will never be plugged by material. We can also provide supplementart bulk bag unloading dust collection systems for the entire plant.

DON'T GET STUCK WITH THIS!

Pan mounted massage paddles unseal the bag and spills

Pan mounted massage paddles unseal the bag and spills

Small access chambers cannot contain the inevitable spills

Access chamber doubles as a hopper, creating a mess, with no containment

Clamping systems without a chamber caused spills.

Clamping systems without a chamber caused spills.

Contact Us - Guaranteed Response within 24 Hours!